UNIT 1

VIRTUAL, ADVANCED AND ADDITIVE MANUFACTURING

virtual, Advanced and Additive Manufacturing Unit is a highly capable unit that provides support and guidance to manufacturing activities in ASEAN region on transformation and adaptation towards ecosystem of advance manufacturing processes. The unit presents multi-platform digital manufacturing solutions for its clients ranging from MSC Software, Altair, Autodesk and Dassault Systèmes in producing digital model and simulation for manufacturing ecosystem. The unit will offer specialized Advanced Additive Manufacturing Laboratory (AAML) where companies enable to experience total solutions of additive manufacturing approach with our technology partners such as Professorship of Virtual Production Engineering (ViF), Technical University of Chemnitz, Germany and Advanced Manufacturing Research Centre (AMRC), University of

Sheffield, UK.

RESEARCH

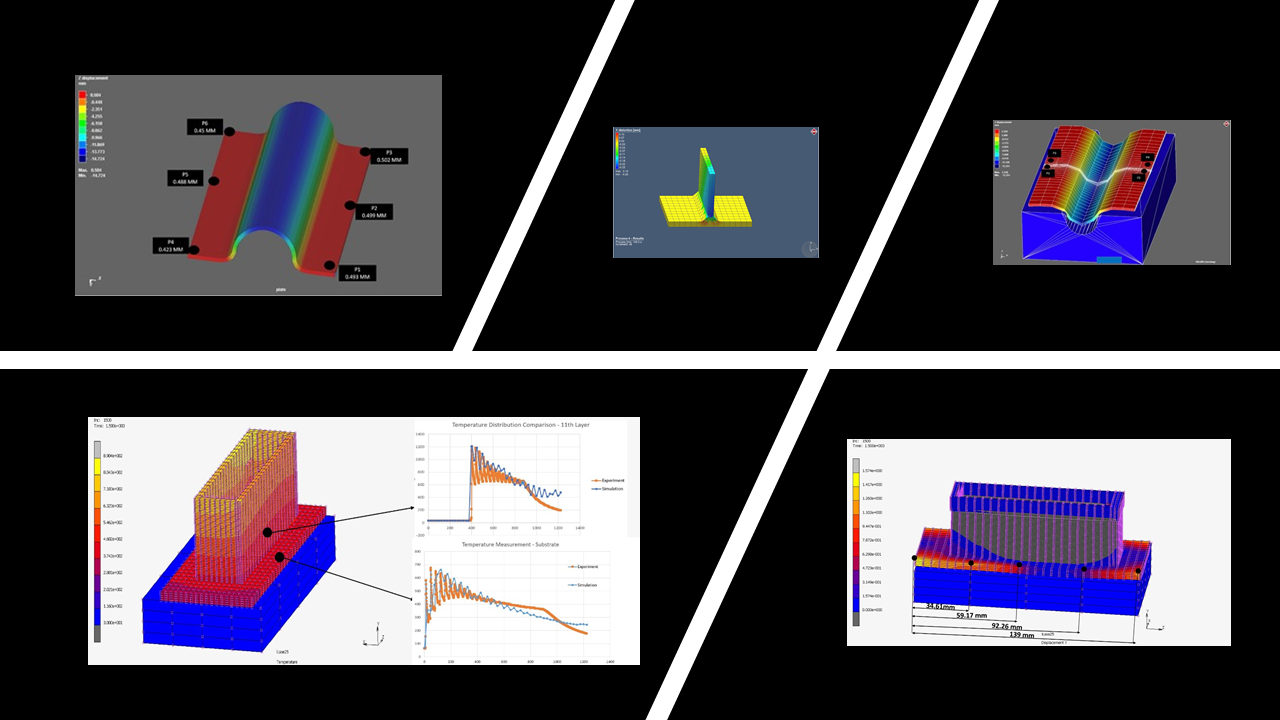

Scientific research for the unit focuses on simulations and experimental approach for manufacturing processes. Manufacturing, Dynamics & Numerical Computation Unit provides essential simulation solutions, experimental approach and laboratory testing & characterization for contractual research with industries. Offering for the research works cover the usage of advanced robotic welding system, testing on static and dynamic loading and characterization using Scanning Electron Microscope (SEM) & X-ray Diffraction (XRD) system.

CONSULTANCY

Manufacturing, Dynamics & Numerical Computation Unit offers consultation works with regards to design and simulation, as well as feasibility studies on manufacturing processes for product development. With unit members that have experience handling industrial consultation works, the range of offering covers from manufacturing processes, vibration analysis, finite element analysis to computational fluid dynamics. The outcome from consultations are in the form of technical report for testing and specification.

TRAINING

Manufacturing, Dynamics & Numerical Computation Unit offers training in using advanced engineering solutions for manufacturing processes, vibration & dynamics, Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD). These offering covers for prearranged monthly training programs and customized on demand training for industries. SMRI will house a state-of-the-art training center that can meet the industrial need with technologically advanced system, comfortable, aesthetically-pleasing, and ease of accessibility. The unit also provide free monthly workshops to share the latest available technology for manufacturing process solutions.

Facilities & Expertise

- 3D Printer (polymer)

- Metal 3D Printer (Upcoming)

- CNC Machine

- Vacuum Casting

- Rapid Prototyping

- CNC Plasma Cutter

- EDM Wirecut

- Arc Spectrometer

- Robotic Welding

- Injection Moulding Machine

- Scanning Electron Microscope (SEM)

- X-ray Diffractometer (XRD)

- Roughness Measurement Machine

- Universal Testing Machine

- Coordinate Measuring Machine (CMM)

- Complete Material Science Laboratory

- 3D-printers

DYNAMICS

- Vibration Analyzer

- Multichannel Analyzer

- B & K Sensors & Accelerometers

- Training Machine for Rotating Machineries

NUMERICAL COMPUTATION

- SimuFact – Manufacturing Processes Simulation

- Nastran/Patran – Finite Element Analysis (FEA)

- Altair Hyperworks Simulation Suite (Upcoming)

- ANSYS

- OpenFOAM – customized numerical solver for Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD)

- Manufacturing Processes Simulation

- Additive Manufacturing

- Welding Consultation

- Material Analysis and Characterization

- Dynamics and Vibration Consultation

- Structural Analysis (FEA)

- Fluid Flow Analysis (CFD)

- Plant Energy Management